Project Overview

Zhengsai Shield has learned that the areas requiring backfill for this project are: Axes AU/1-13, with a quantity of 97.7m (length) X 0.8m (width) X 5.6m (height) = 438m³; and Axes 13/AV-BK, with a quantity of 46.1m (length) X 0.8m (width) X 5.6m (height) = 207m³. The foundation pit depth is 5.6 meters, and the distance between the underground structure and the support structure is 0.8 meters. The backfill requirements are: 0.4 MPa strength in 7 days and 0.8 MPa strength in 28 days. After careful consideration, it is decided to use the fluidized soil-forming material developed by Zhengsai Repair for trench backfill.

Fluidized Soil-forming Material for Trench Backfill Process

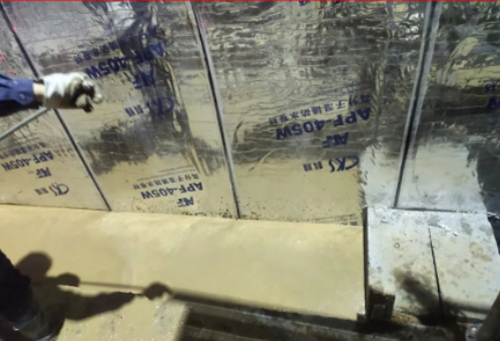

After an on-site investigation, it was found that the construction site is narrow and does not have the conditions for direct dumping by concrete mixer trucks. After the construction on the top of the garage is completed, soil will be sourced locally for mixing and chute backfill.

The fluidized soil-forming material trench backfill process includes:

1.Determine the stockyard location near the outer wall of the underground room on site.

2.Transport and source the soil.

3.Use a small excavator to mix and crush the soil, adding water during mixing.

4.Add soil rock-forming agent.

5.Conduct chute backfill.

6.Finish and cure the surface.

7.Achieve the desired molding effect.

+86 15137139713

Building 12, Shangjin Street, Zhengzhou City, Henan Province, China

FrankWangRD@gmail.com

Fuzhou.Wang@zhengsai-international.com