RD-A Waterproof and Anti-permeation Slurry for Negative Side Waterproofing is a gray powder primarily composed of high-performance silicate and sand, enhanced with dozens of chemical elements as activators and a trace amount of rubber powder. When mixed with water, it initiates an electrochemical reaction, decomposing cement particles and activating the metal elements within the cement to achieve complete hydration of the cement particles. This results in high density, high impermeability, and high bond strength.

RD-A Anti-permeation Slurry and One-Spray Waterproofing Agent for Negative Side are available as gray or white powders, consisting of high-performance silicate, 200-mesh sand, an appropriate amount of activator, and hydrating agent. Upon adding water, a series of oxidation reactions occur, activating the inert components in Portland cement, fragmenting cement particles, and reducing the pore size from the usual 40 µm to 60 µm to 5 µm to 15 µm. The concrete pores are improved from 500 Å to 10,000 Å to less than 4 Å (the diameter of a water molecule is 4 Å), thereby achieving leakage prevention.

When cracks appear in the concrete, water enters the cracks and pores, activating the active substances, causing the crystals inside the pores to expand and reach an atmospheric pressure balance inside and outside, thus continuously achieving a sealing effect. This process is dynamic. When used alone, it can withstand a backwater pressure of 150 meters of water column. The difference between RD-A Special Waterproof and Anti-permeation Slurry and One-Spray Waterproofing Agent for Negative Side is that the latter has a faster curing time, making it suitable for areas with severe water seepage.

Excellent waterproof and anti-permeation capabilities, providing true multiple dynamic waterproofing.

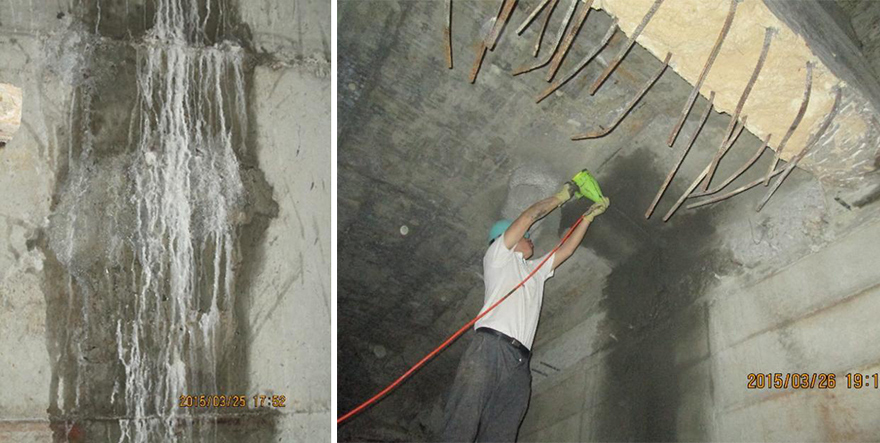

Superior bonding ability with concrete and masonry structures, allowing for operation with water present, achieving excellent results in complex negative side waterproofing scenarios.

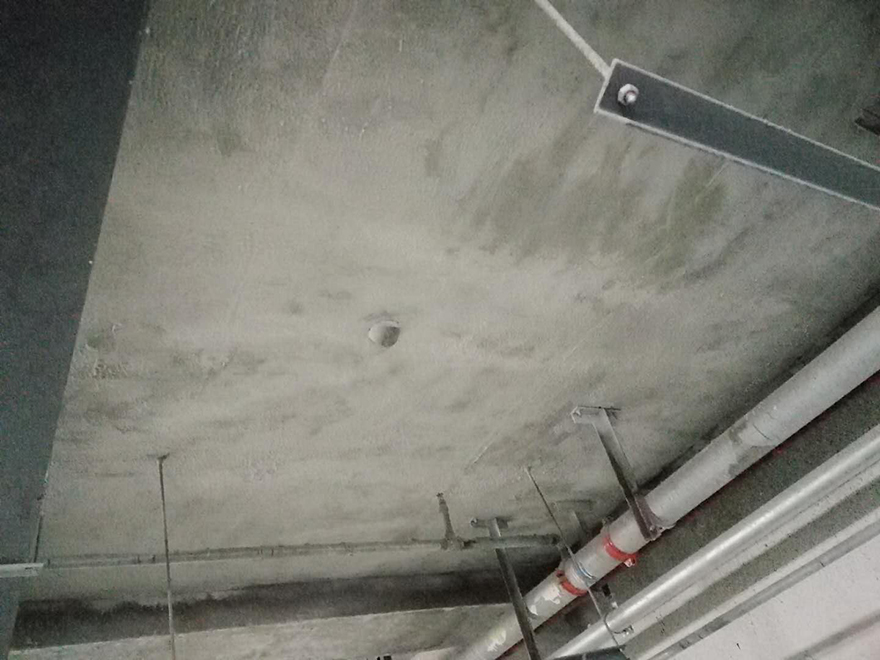

High-efficiency high-pressure spray technology ensures uniform thickness and seamless construction. The material thickness can be adjusted according to construction needs, making it suitable for both localized repairs and large-area applications.

Integrates waterproofing, anti-permeation, repair, reinforcement, and protection into a single application, eliminating the need for an additional protective layer. It exhibits high compressive and flexural strengths, as sturdy as concrete, capable of withstanding high leakage pressures and effectively increasing building strength.

Offers an extended service life, resistance to high temperatures, UV rays, freezing, and aging, with an overall lifespan close to that of concrete.

A truly eco-friendly product suitable for use in food engineering and drinking water projects.

This product is particularly suitable for the back treatment of leaks in concrete and masonry structures and can be used for passive waterproofing on the negative side. The construction process of cement-based waterproof materials is simple, and being primarily composed of Portland cement, it has excellent compatibility with cement concrete, the main material in civil and infrastructure construction projects.

It is mainly used in the following scenarios: tunnels, wells, reservoirs, water and wastewater treatment facilities, elevator pits, underground concrete structures, swimming pools, and anti-leakage and sealing projects for cooling tower pits.

+86 15137139713

Building 12, Shangjin Street, Zhengzhou City, Henan Province, China

FrankWangRD@gmail.com

Fuzhou.Wang@zhengsai-international.com