It is available in gray or white powder form, consisting of high-performance silicate, 200-mesh sand, an appropriate amount of activator, hydrating agent, and preservative. Upon adding water, a series of oxidation reactions occur, activating the inert components in Portland cement, disintegrating cement particles, and transforming capillary pores from the usual 40 µm to 60 µm to 5 µm to 15 µm. It improves concrete capillary pores from 500 Å to 10,000 Å to less than 4 Å (the diameter of a water molecule is 4 Å), thereby achieving a sealing effect for anti-corrosion and impermeability.

| Initial Setting Time | 142 minutes |

| Compressive Strength | 33.7 MPa (7 days); 40.7 MPa (28 days) |

| Flexural Strength | 8.4 MPa (7 days); 9.4 MPa (28 days) |

| Impermeability Pressure | 1.8 MPa |

| Bond Strength | 1.23 MPa |

| Crack Resistance (Cracking Index) | 152.5 mm |

| Shrinkage Rate | 0.08% (28 days) |

| Freeze-Thaw Cycles | 150 cycles |

| Chloride Ion Diffusion Coefficient | 1.9×10-2 m²/s (28 days) |

| Reinforcement Corrosion | No corrosion hazard to reinforcement |

| Acid Resistance (mass fraction 25% H2SO4 solution, mass loss after 7 days) | 4.8% |

| Alkali Resistance (mass fraction 35% NaOH solution, 7 days, compressive strength ratio) | 100.8% |

| Salt Resistance (mass fraction 20% Na2SO4 solution, 7 days, compressive strength ratio) | 93.2% |

| High Temperature Resistance (200°C for 7 days, mass loss) | 2.4% |

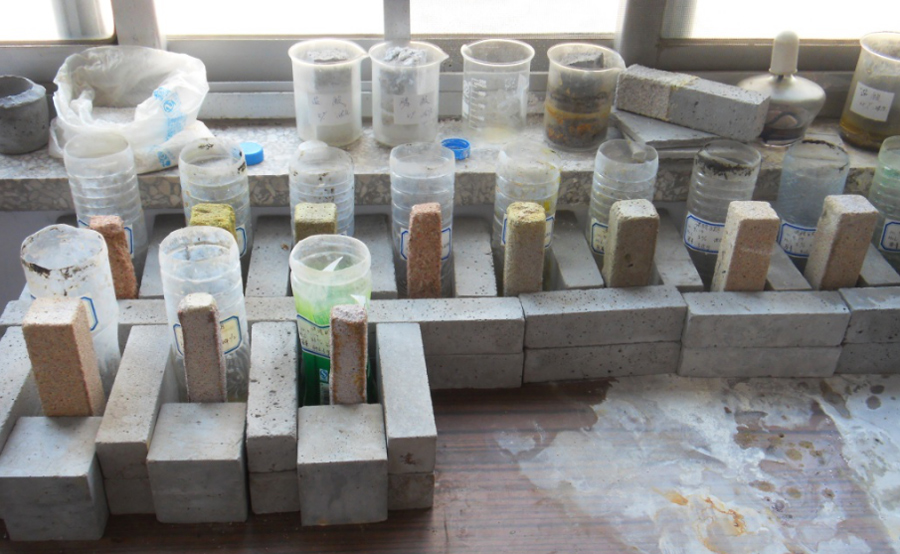

After 45 days, ordinary test blocks have suffered severe corrosion and lost strength;

However, RD-B test blocks, although exhibiting surface sanding-like phenomena, still maintain high internal strength and impermeability.

| Name | Weight Before Immersion (g) | Weight After Immersion (g) | Percentage of Weight Reduction |

| High-Alumina Mortar | 507.3 | 272.7 | 46% |

| RD-B | 527 | 433.3 | 18% |

| YYH | 576.3 | 490.5 | 15% |

| Name | Weight Before Immersion (g) | Weight After Immersion (g) | Percentage of Weight Reduction |

| High-Alumina Mortar | 511 | 268.8 | 47% |

| RD-B | 528.6 | 392.9 | 26% |

| YYH | 579 | 491.1 | 15% |

| Name | Weight Before Immersion (g) | Weight After Immersion (g) | Percentage of Weight Reduction |

| High-Alumina Mortar | <509 | <452.5 | <11% |

| RD-B | <535 | <511.9 | <4.3% |

| YYH | <533.5 | <510.1 | <4.3% |

With acid resistance and chemical resistance, it can be used in sewage treatment tanks, acid storage tanks, oil tanks, acid-resistant floors, chemical plant storage towers, etc.

With frost resistance, it can be used in freezers, cold storage rooms, and places with large temperature fluctuations.

Resistant to chloride ion erosion from seawater, it can be used in offshore buildings, embankments, docks, and fortifications.

With low hydration heat and resistance to drying shrinkage and cracking, it can be used in reservoir concrete, dam concrete grout layers, bridge concrete grout layers, concrete pavement mortar layers, etc.

Repair of defects in old concrete and engineering reinforcement.

+86 15137139713

Building 12, Shangjin Street, Zhengzhou City, Henan Province, China

FrankWangRD@gmail.com

Fuzhou.Wang@zhengsai-international.com